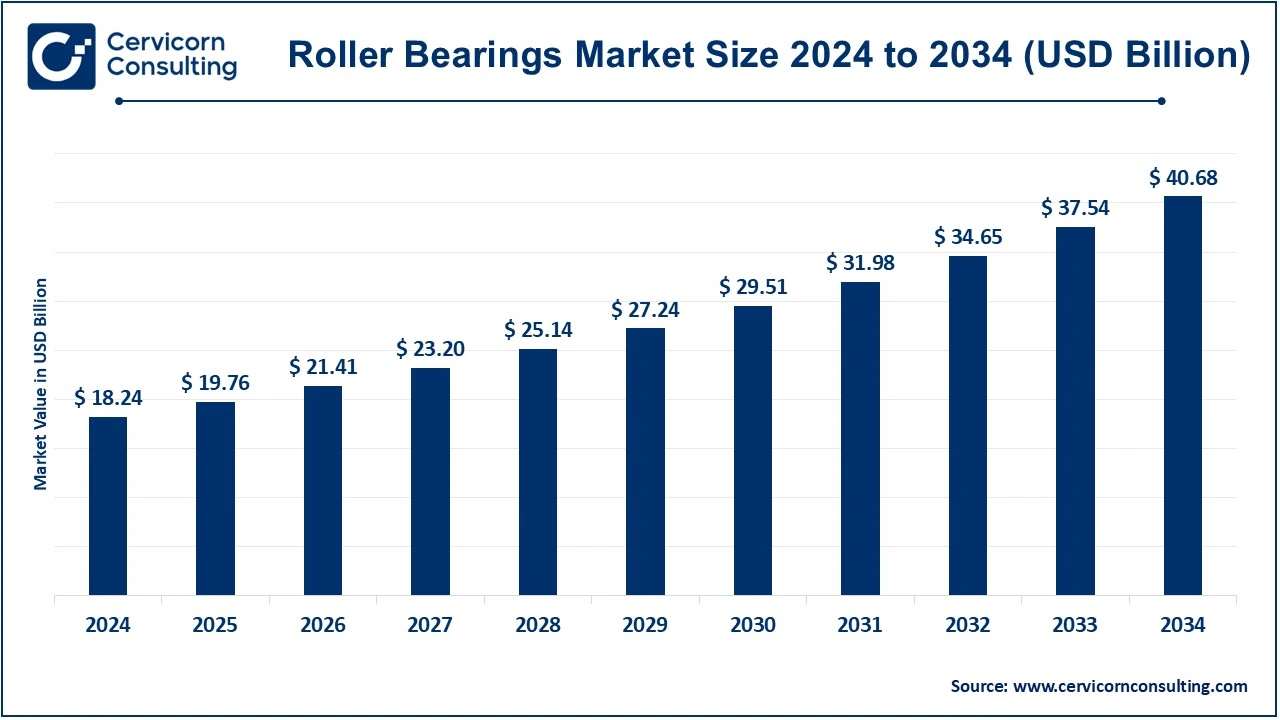

Roller Bearings Market Overview

In 2024, the global roller bearings market stood at nearly USD 18.24 billion and is forecasted to climb to USD 40.68 billion by 2034, progressing at a CAGR of 8.35% between 2025 and 2034. This expansion is largely attributed to advancements in technology, rapid adoption of industrial automation, the growing penetration of electric vehicles (EVs), and a stronger emphasis on energy-efficient equipment.

Roller bearings are indispensable components that minimize friction in rotating systems by utilizing cylindrical, spherical, or tapered rollers. They not only support both axial and radial loads but also enhance the reliability, durability, and efficiency of machinery across industries such as automotive, aerospace, construction, energy, and heavy industrial machinery.

👉 Get a Free Sample: https://www.cervicornconsulting.com/sample/2512

Key Market Trends

-

Digitalization and Smart Bearings

IoT-enabled bearings are revolutionizing maintenance strategies by enabling real-time monitoring of load, vibration, and temperature. Leading players like SKF have developed smart bearing systems that reduce unplanned downtime, optimize efficiency, and support predictive maintenance—especially vital in sectors like automotive, aerospace, and industrial machinery. -

Sustainability and Eco-friendly Materials

Growing pressure to align with global sustainability mandates is driving adoption of energy-efficient and low-friction bearings. For instance, Schaeffler India Limited is leveraging greener lubricants and advanced materials to lower carbon footprints in industrial applications. -

Acceleration of Electric Vehicle Adoption

EV growth has intensified the demand for specialized lightweight and high-performance roller bearings capable of handling higher rotational speeds. Companies such as JTEKT India Limited and NRB Bearings Limited are broadening their EV-focused product offerings to capture this rising opportunity. -

Advancements in Manufacturing & Materials

The development of high-strength alloys, ceramic hybrid bearings, and precision-engineered designs is improving durability and expanding use cases in harsh environments such as aerospace and wind energy. NTN Corporation and Nachi-Fujikoshi Corp are at the forefront of these innovations. -

Industry 4.0 & Automation Integration

The rise of smart factories and robotics has heightened the demand for highly reliable, low-maintenance bearings. This integration supports the seamless functioning of automated systems within logistics and manufacturing.

Market Drivers

-

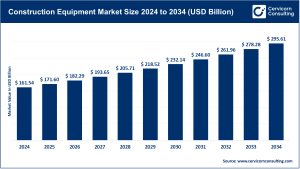

Rising Demand from Automotive and Industrial Sectors

Automotive production—especially EVs and hybrids—remains a major contributor to roller bearing demand, with Asia-Pacific emerging as a hub. Industrial applications in mining, energy, and construction also provide sustained market momentum. -

Continuous Technological Innovation

New-generation bearings with IoT features, hybrid ceramic designs, and enhanced coatings are increasing operational life and efficiency, encouraging adoption across critical industries. -

Government Initiatives and Infrastructure Growth

Infrastructure and industrial expansion programs in India, China, and the Middle East are spurring demand for heavy-duty bearings. Policies incentivizing EV adoption, renewable energy, and energy-efficient machinery are generating billion-dollar opportunities, especially in wind turbines and electric mobility. -

Shift Toward Energy Efficiency

Manufacturers are increasingly adopting high-efficiency, low-friction bearings to meet energy-saving goals across automotive, renewable, and industrial manufacturing sectors.

Impact of Trends and Drivers

-

Automotive: Precision bearings enhance drivetrain performance in EVs, reducing maintenance costs and boosting efficiency.

-

Industrial Machinery: Smart bearings allow predictive maintenance, minimizing downtime and extending machine life cycles.

-

Regional Outlook: Asia-Pacific benefits most from rapid urbanization and industrialization, while North America and Europe focus on sustainability and digital manufacturing.

-

Renewable Energy: Bearings engineered for wind turbines are gaining traction due to corrosion-resistant and high-strength material innovations.

Challenges & Opportunities

-

Challenges: High upfront costs for advanced and smart bearings, volatility in raw material prices, and intense competition among global and regional players.

-

Opportunities: Accelerated EV penetration, Industry 4.0 adoption, and renewable energy expansion open new revenue streams for companies developing energy-efficient and intelligent bearing solutions.

Future Outlook

The roller bearings market is poised for strong growth, shaped by digitalization, eco-friendly designs, EV-specific solutions, and Industry 4.0 integration. With a projected value of USD 40.68 billion by 2034, companies investing in R&D for smarter, durable, and sustainable bearings will gain competitive advantage across automotive, aerospace, energy, and industrial sectors.

📌 Contact Us for a Detailed Overview: Click here