Market Overview

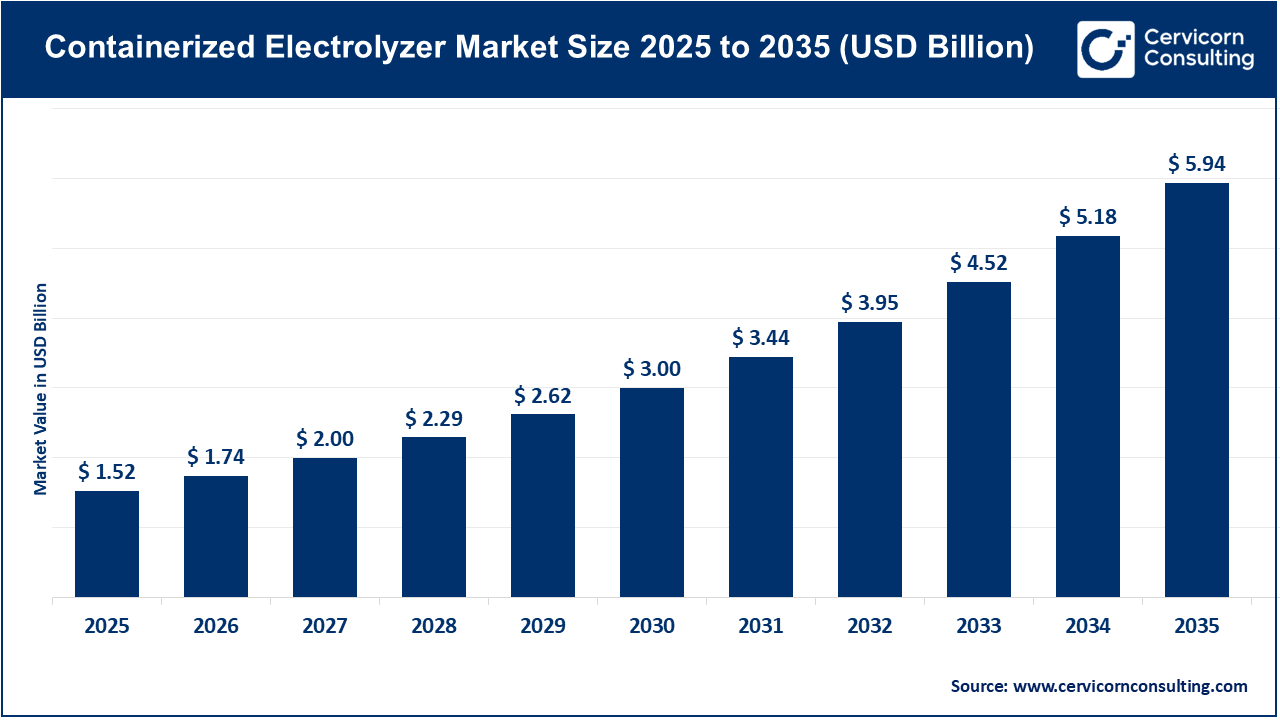

The global containerized electrolyzer market is witnessing remarkable momentum as hydrogen solidifies its role as a cornerstone of the worldwide clean energy transition. The market was estimated at around USD 1.52 billion in 2025 and is forecast to climb to nearly USD 5.94 billion by 2035, registering a CAGR of roughly 14.6% between 2025 and 2034.

Containerized electrolyzers are self-contained, modular hydrogen generation units—commonly based on alkaline, PEM (Proton Exchange Membrane), or AEM (Anion Exchange Membrane) technologies—packaged within portable container systems. These compact units feature a plug-and-play configuration, enabling quick deployment, adaptable scaling, and decentralized hydrogen production.

Their modular structure supports a variety of applications, including off-grid energy generation, integration with renewable sources, industrial decarbonization, refueling stations, and mobile hydrogen infrastructure. As a result, containerized electrolyzers have become a vital component of the growing global hydrogen ecosystem.

👉 Get a Free Sample: https://www.cervicornconsulting.com/sample/2805

Key Market Trends

1. Modular and Scalable Hydrogen Systems

The market is experiencing a paradigm shift toward modular and flexible hydrogen production. Containerized electrolyzers—typically housed in 20- or 40-foot ISO containers—simplify logistics, minimize on-site engineering, and cut installation times significantly.

Solutions such as Enapter’s AEM EL 2.1 systems and Siemens Energy’s containerized Silyzer modules exemplify this movement, helping accelerate project execution and lower operational costs for distributed hydrogen applications. This modular trend is particularly transforming industrial, transportation, and renewable energy sectors.

2. Integration with Renewable Energy Infrastructure

An emerging trend involves coupling containerized electrolyzers with solar and wind energy assets to convert surplus electricity into hydrogen. This not only enhances grid stability but also facilitates energy storage and conversion.

Nations like Germany, Japan, and Australia are actively implementing Power-to-X projects, using hydrogen as a medium to balance renewable intermittency and promote sustainable power systems.

3. Growth in Decentralized and Mobile Hydrogen Production

Unlike traditional centralized hydrogen plants that demand heavy capital investment, containerized systems promote distributed, on-demand hydrogen production. They are ideal for remote, temporary, or off-grid environments such as mining operations, maritime hubs, and emergency energy systems.

This decentralization aligns with the trend of energy democratization, empowering regions to generate clean hydrogen locally without depending on large-scale industrial complexes.

4. Government Support for Hydrogen Infrastructure

Governments worldwide—especially across Europe, North America, and Asia-Pacific—are actively backing containerized electrolyzers through policy incentives, grants, and subsidies.

For instance, the EU’s REPowerEU initiative targets the production of 10 million tonnes of renewable hydrogen by 2030, while the U.S. Hydrogen Hubs program is channeling billions into decentralized hydrogen infrastructure. Such initiatives are spurring investments in compact, container-based hydrogen systems.

5. Cost Optimization through Mass Manufacturing

With rapid advancements in stack design, automation, and large-scale production, electrolyzer costs have fallen considerably. Leading companies like Nel ASA, McPhy Energy, and Enapter AG are expanding manufacturing capacity through gigafactories to achieve economies of scale. This is improving affordability and reliability, driving mainstream adoption of containerized electrolyzer solutions.

Market Drivers

1. Growing Demand for Green Hydrogen

The surge in green hydrogen demand—produced from renewable-powered electrolysis—is one of the most powerful forces behind market growth. This form of hydrogen plays a critical role in decarbonizing energy-intensive sectors such as steel, chemicals, and transportation.

The International Energy Agency (IEA) anticipates global hydrogen demand could triple by 2050, presenting vast opportunities for containerized electrolyzers that support flexible and localized production.

2. Advances in Electrolysis Technologies

Continuous innovation in PEM and AEM electrolyzer technology is enhancing efficiency and reducing cost per kilogram of hydrogen. These systems are compact, highly responsive, and well-suited to intermittent renewable power, making them ideal for containerized configurations.

3. Increasing Government Initiatives

Supportive government frameworks and public-private investments are expediting global adoption.

Examples include:

-

Europe’s Hydrogen IPCEI program, which funds modular hydrogen systems.

-

The U.S. Inflation Reduction Act (IRA), providing lucrative production tax credits for renewable hydrogen.

-

India’s National Green Hydrogen Mission, promoting distributed generation models and pilot installations.

4. Industrial Decarbonization Commitments

Industries are deploying on-site containerized systems to transition from fossil-based hydrogen to low-carbon alternatives. Sectors like refining, ammonia, and freight logistics are integrating modular solutions to meet carbon neutrality goals and comply with tightening environmental regulations.

5. Demand for Energy Security and Remote Solutions

Containerized electrolyzers enable independent hydrogen production in off-grid or resource-limited environments, providing resilience against supply chain disruptions. Their adaptability makes them crucial for disaster response, defense installations, and rural electrification projects.

Impact of Trends and Drivers

The synergy between these factors is profoundly reshaping the global hydrogen landscape:

-

Industrial transformation: Major industries are adopting modular electrolyzers for pilot decarbonization projects, paving the way for scalable green hydrogen use.

-

Regional dynamics: Europe leads in adoption due to robust policy frameworks, while Asia-Pacific is emerging as a manufacturing hub.

-

Accelerated energy transition: Integrating hydrogen with renewable assets is strengthening grid resilience and storage capabilities.

-

Infrastructure development: Containerized electrolyzers are shortening deployment timelines for hydrogen refueling networks, supporting the growth of fuel-cell mobility.

Challenges and Opportunities

Challenges

-

High initial capital costs: While prices are dropping, container fabrication and integration remain expensive.

-

Lack of standardization: Variations in container design and regional safety regulations slow international scalability.

-

Dependence on renewable power availability: Cost-effective operation relies heavily on access to low-cost, continuous renewable electricity.

Opportunities

-

Expansion of Hydrogen Hubs: Emerging energy clusters in the U.S., Middle East, and Asia-Pacific are boosting demand for portable electrolyzers.

-

Collaborative innovation: Partnerships between electrolyzer manufacturers and renewable developers are yielding breakthroughs in system performance.

-

Rise of decentralized grids: Growing interest in microgrids and community-scale hydrogen networks presents long-term growth potential.

Future Outlook

The containerized electrolyzer market is set for exponential growth, projected to exceed USD 5.9 billion by 2035, advancing at a CAGR of roughly 14.6%.

Key growth determinants will include:

-

Expansion of electrolyzer gigafactories to reduce per-unit costs.

-

Rising adoption in developing economies, particularly for renewable-integrated hydrogen projects.

-

Standardization efforts that streamline cross-border deployment.

-

Integration of AI and digital controls to enhance operational efficiency and predictive maintenance.

As the global shift toward green hydrogen accelerates, containerized electrolyzers are positioned to become the backbone of a decentralized and resilient hydrogen infrastructure, supporting industrial decarbonization, sustainable mobility, and global energy independence.

👉 To Get Detailed Overview, Contact Us: https://www.cervicornconsulting.com/contact-us