1. Market Overview

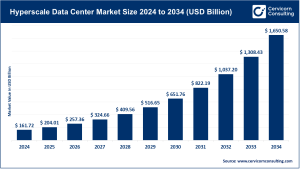

The global advanced robotics market reached an estimated USD 45.43 billion in 2024 and is forecasted to surge to around USD 246.02 billion by 2034, reflecting an impressive CAGR of 19.09% throughout the assessment period.

Advanced robotics encompasses next-generation robotic systems equipped with artificial intelligence, machine learning, high-precision sensors, perception technologies, and autonomous decision-making capabilities. Unlike traditional industrial robots, these sophisticated systems can interpret their environments, learn from real-time data, and work collaboratively with humans, enabling them to perform complex activities across diverse sectors.

The rapid expansion of this market is being accelerated by enterprise-wide digital transformation, intensifying labor shortages, rising automation needs, and continuous advancements in robotics technologies.

Get a Free Sample: https://www.cervicornconsulting.com/sample/2383

2. Key Market Trends

According to Cervicorn Consulting, several transformative trends are shaping the landscape of advanced robotics:

Adoption of AI-Integrated Smart Robotics

Robots are increasingly being built with embedded AI, ML algorithms, IoT connectivity, and advanced analytics. These intelligent machines can autonomously adjust their operations, analyze data, and optimize workflows. For instance, predictive analytics in smart factories now enables robots to preempt maintenance issues, improving efficiency and reducing operational downtime.

Rise of Modular & Prefabricated Robotics

Manufacturers are shifting toward modular robotic systems that can be assembled off-site and quickly deployed in operational environments. This approach enhances scalability, lowers installation costs, and enables users to reconfigure or expand robotic setups with minimal disruption.

Use of Lightweight & Sustainable Materials

Growing environmental awareness is influencing robot design. Companies are increasingly incorporating lightweight composites, carbon fiber, recycled materials, and eco-friendly alternatives to reduce energy consumption and enhance performance while lowering the ecological footprint.

Human–Robot Collaboration (Cobots) and Enhanced Safety

As robots operate more closely with human workers, safety technologies—such as real-time collision detection, force-limiting mechanisms, and advanced sensing—are becoming essential. These trends are boosting the adoption of collaborative robots in industries like manufacturing, logistics, and customer service.

Shift Toward Integrated, End-to-End Robotics Ecosystems

The market is moving away from standalone robotic hardware toward complete ecosystems that include AI software, control units, sensors, and digital platforms. These integrated systems deliver superior ROI, streamline deployment, and simplify management.

3. Market Drivers

Multiple forces are accelerating market adoption and technological progress in advanced robotics:

Surging Investment and Financial Support

Government funding, subsidies, innovation grants, and private-sector investments are expanding R&D capabilities. Such financial support is enabling breakthroughs in autonomous systems, smart factories, and next-generation automation tools.

Labor Constraints & Rising Wages

A shrinking workforce in many developed nations, combined with escalating labor costs, is pushing businesses to automate repetitive or high-precision tasks. Robots help improve operational output and reduce reliance on manual labor.

Booming E-Commerce & Logistics Industry

The rise of online retail is fueling unprecedented demand for warehouse automation. Autonomous mobile robots (AMRs) and AGVs are becoming essential tools for managing inventory, processing orders, and handling large-scale fulfillment operations.

Industry 4.0 & Smart Manufacturing

Advanced robotics plays a central role in digital transformation strategies—enabling predictive maintenance, intelligent quality control, and agile production lines. These capabilities are integral to Industry 4.0 implementation.

Safety and Cobot Advancement

Industries with high safety requirements are increasingly adopting collaborative robots equipped with real-time sensing and advanced protective features, supporting safe human–machine interaction.

Sustainability Pressures

The global shift toward environmental responsibility is pushing manufacturers to adopt green robotics solutions that use energy-efficient components, recyclable materials, and modular designs to cut waste.

4. Impact of Trends and Drivers

These factors collectively influence various industries and geographic markets:

Manufacturing and Industrial Automation

The integration of modular robotics, smart sensors, and human–robot collaboration is transforming traditional production environments into dynamic, adaptive ecosystems—especially across high-wage regions like Europe and North America.

Logistics and E-Commerce

Asia-Pacific and North America are witnessing rapid deployment of AMRs and automated systems as fulfillment centers scale to meet rising order volumes driven by online shopping demand.

Healthcare and Service Robotics

Cobots and safe collaborative robots are increasingly used in hospitals, therapy centers, and eldercare settings—particularly in aging populations—enhancing care delivery and reducing workforce strains.

Sustainability and Eco-Friendly Robotics

Regions with strict environmental regulations, such as Europe, are driving demand for green robotics solutions that align with ESG objectives.

Emerging Markets

Government-backed industrialization programs, tax incentives, and modernization initiatives across Asia-Pacific and parts of Latin America are accelerating adoption among small and mid-sized manufacturers. Modular robotics plays a key role by reducing initial investment barriers.

5. Challenges & Opportunities

Challenges

-

High upfront capital investment

-

Integration difficulties with legacy systems

-

Need for specialized workforce training

-

Strict safety regulations and certification requirements

-

Compliance challenges in sensitive sectors like healthcare

Opportunities

-

Growth of the Robotics-as-a-Service (RaaS) business model

-

Expansion into non-traditional fields like agriculture, construction, and personal care

-

Adoption of sustainable robotics for ESG compliance

-

AI-powered automation enabling smarter, flexible, autonomous robots

-

Increasing demand for modular and rapidly deployable robotic systems

6. Future Outlook

The advanced robotics industry is positioned for rapid, long-term expansion, with the market expected to grow from USD 45.43 billion in 2024 to USD 246.02 billion by 2034 at a CAGR of 19.09%, as highlighted by Cervicorn Consulting.

Key future developments include:

-

Deepening convergence of AI, IoT, cloud, and robotics

-

Widespread adoption of RaaS subscription models

-

Increasing emphasis on sustainable, energy-efficient, and modular robot designs

-

Stronger government support for robotics in public infrastructure, healthcare, and smart cities

As these advancements accelerate, advanced robotics will continue to redefine industrial productivity, enhance workplace safety, and drive innovation across multiple sectors—solidifying its role as a cornerstone of the Fourth Industrial Revolution.

To Get Detailed Overview, Contact Us – https://www.cervicornconsulting.com/contact-us