Carbon Black Market Overview

The global carbon black market plays a pivotal role in the chemical and manufacturing sectors. Carbon black, a finely divided form of almost pure carbon, is primarily produced through the incomplete combustion of heavy petroleum feedstocks. It is widely used across various industries, including tires, rubber products, plastics, inks, coatings, and electronics.

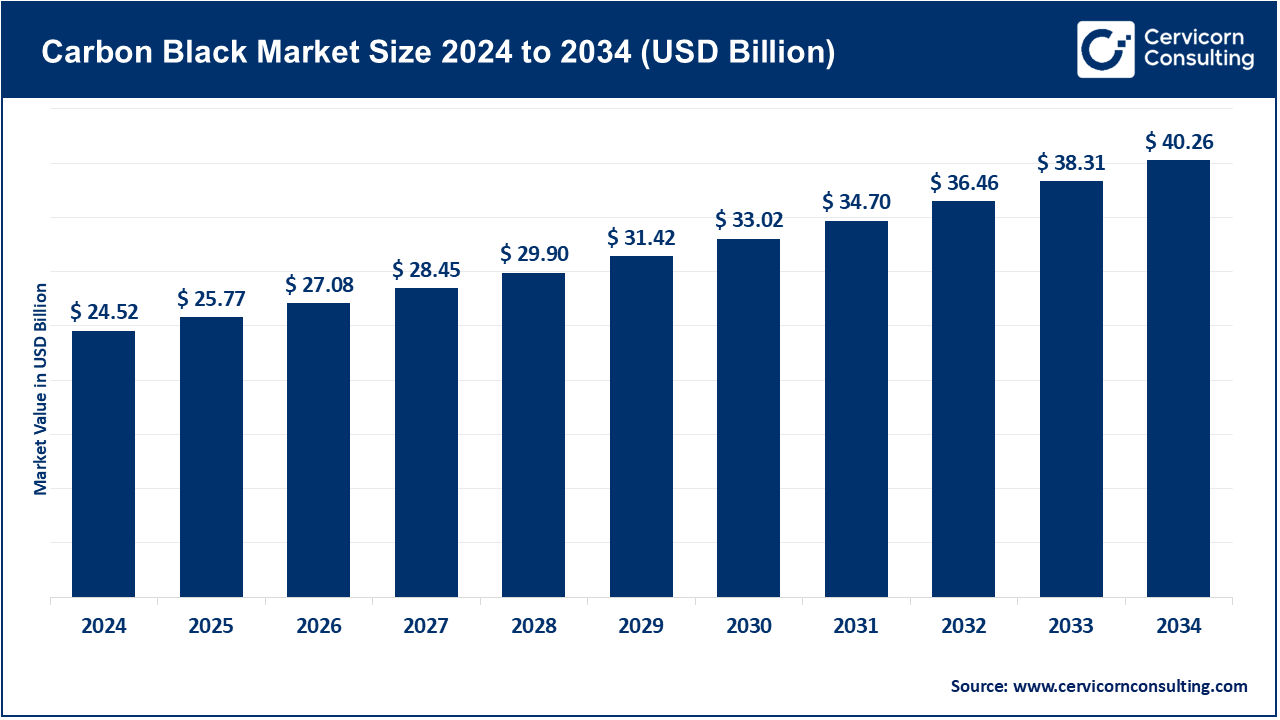

As of 2024, the market is estimated at USD 24.52 billion and is projected to reach approximately USD 40.26 billion by 2034, growing at a CAGR of 5.1% from 2025 to 2034. This growth is driven by increasing automotive production, rising demand for high-performance tires, and expanding applications in emerging sectors such as electronics and 3D printing. Source

Key Market Trends

Several trends are currently shaping the carbon black market:

1. Shift Toward Sustainable and Specialty Carbon Black

Manufacturers are increasingly producing eco-friendly carbon black using renewable feedstocks and innovative processes to minimize environmental impact. For instance, investments in gas furnace carbon black technologies are helping reduce emissions while enhancing product quality.

2. Technological Advancements in Tire and Rubber Industries

Carbon black is essential for reinforcing tires and improving wear resistance. The introduction of high-dispersion and ultra-fine carbon black grades boosts tire performance and contributes to better fuel efficiency.

3. Regulatory Pressure on Emissions

Global environmental regulations are becoming stricter, particularly concerning air pollutants and greenhouse gas emissions from carbon black production. This has prompted companies to adopt cleaner technologies and closed-loop production systems.

4. Rising Demand from Emerging Applications

Beyond traditional tires and rubber, carbon black is increasingly used in conductive polymers, inks, coatings, and 3D printing filaments, broadening its market applications.

5. Digitalization and Smart Manufacturing

The adoption of AI, IoT, and real-time monitoring in production processes enhances efficiency and product consistency, helping manufacturers meet rising quality standards and market demands.

Market Drivers

The carbon black market is propelled by multiple factors:

-

Automotive Industry Expansion: Growing global vehicle production, particularly in Asia-Pacific, drives higher demand for tires and rubber products, boosting carbon black consumption.

-

Urbanization and Industrialization: Expanding infrastructure and construction activities fuel demand for plastics, inks, and coatings, where carbon black serves as a key ingredient.

-

Government Initiatives: Policies supporting eco-friendly production and industrial sustainability promote the development of specialty and low-emission carbon black.

-

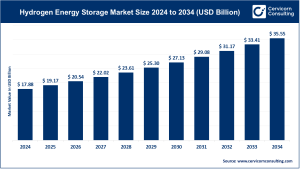

Technological Innovations: Advances in high-performance grades and specialized carbon black facilitate new applications in electronics, energy storage, and 3D printing.

Notably, the tire industry consumes over 70% of global carbon black, highlighting its strong correlation with automotive growth.

Impact of Trends and Drivers

These trends and growth factors affect different market segments in several ways:

-

By Product Type: Specialty and conductive carbon black segments are witnessing faster expansion due to high-tech applications.

-

By End-Use Industry: While the automotive segment remains dominant, electronics, inks, and coatings are gaining significant market share.

-

By Region: Asia-Pacific, led by China and India, remains the largest market due to rapid industrial and automotive expansion. Meanwhile, North America and Europe are emphasizing sustainable and specialty carbon black production.

Challenges & Opportunities

Challenges:

-

Environmental concerns and strict compliance requirements increase production costs.

-

Fluctuating raw material prices can impact profitability.

Opportunities:

-

Rising demand for eco-friendly and specialty grades presents high-value growth prospects.

-

Expanding applications in electronics, energy storage, and advanced manufacturing offer avenues for diversification.

Future Outlook

Emerging trends, including sustainable production, high-performance specialty grades, and increasing use in electronics and 3D printing, are expected to drive market dynamics. Manufacturers investing in innovation and environmentally compliant technologies are well-positioned to capture significant market share in the upcoming decade.

For a more detailed market analysis, visit Cervicorn Consulting