Powder Coatings Market Overview

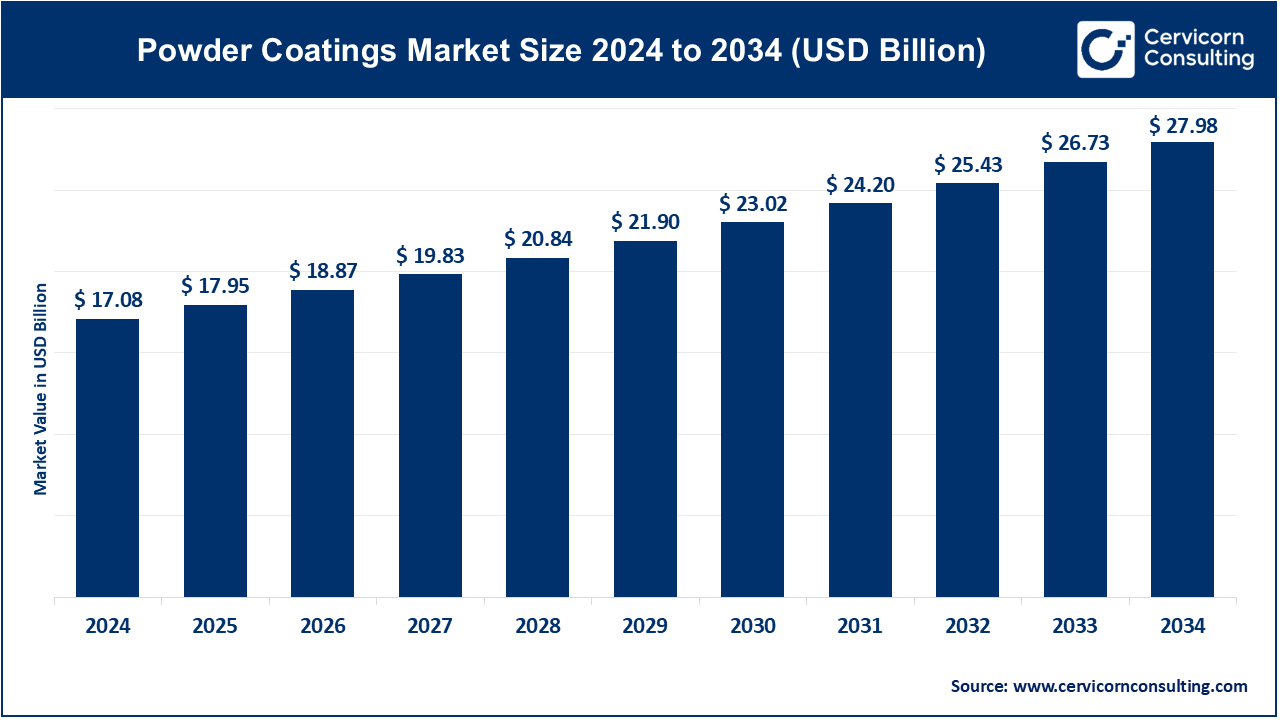

In 2024, the global powder coatings market was valued at approximately USD 17.08 billion and is expected to exceed USD 27.98 billion by 2034, growing at a CAGR of 5.05% from 2025 to 2034. The market’s growth is driven by rapid industrialization, increased adoption of eco-friendly coatings, and expansion in emerging economies.

Powder coatings are a key segment of the coatings industry, valued for their environmental benefits, durability, and versatility. These coatings are applied as a free-flowing, electrostatically charged powder that is cured under heat to form a hard, protective finish. Applications span automotive, construction, appliances, and industrial equipment sectors.

Get a Free Sample: https://www.cervicornconsulting.com/sample/2333

Key Market Trends

Technological Innovations in Coatings Formulation:

Manufacturers are developing advanced powder coating formulations, including ultra-durable, high-performance, and anti-corrosion variants. Thermoplastic and epoxy-based powders, for example, enhance both product longevity and application efficiency.

Sustainability and Eco-Friendly Demand:

Stricter VOC emission regulations are driving the adoption of environmentally friendly coatings. Waterborne and solvent-free powder coatings are gaining prominence, especially in Europe and North America.

Expansion in Automotive and Industrial Applications:

The automotive sector increasingly uses powder coatings for parts due to their resistance to chipping, scratching, and UV damage. Industrial machinery and construction equipment also benefit from corrosion-resistant finishes.

Digital and Automated Application Processes:

Automation and digital monitoring improve efficiency, minimize waste, and ensure consistent coating quality. Robotics and IoT-enabled spray systems are becoming standard in large-scale production.

Customization and Aesthetic Innovations:

Consumer demand for visually appealing finishes is driving innovations in texture, color, and metallic effects, particularly in appliances and furniture.

Market Drivers

-

Rising Industrialization and Construction: Industrial expansion, particularly in Asia-Pacific, increases demand for durable, protective coatings. Urban development drives powder-coated metal usage in residential and commercial projects.

-

Government Regulations and Incentives: Policies promoting low-VOC and eco-friendly coatings encourage manufacturers to adopt powder solutions, often supported by tax incentives and compliance programs.

-

Technological Advancements: Innovations such as low-temperature curing and electrostatic spray methods reduce production costs and expand application possibilities.

-

Growing Demand for Automotive and Consumer Electronics: Powder coatings improve durability and aesthetics of vehicles, appliances, and electronics, aligning with consumer expectations for high-quality products.

Impact of Trends and Drivers

-

Automotive Segment: Durable, anti-corrosion coatings lower maintenance costs and extend product life.

-

Construction & Infrastructure: Urbanization drives use of protective and decorative coatings on metal structures.

-

Regional Influence: Asia-Pacific leads in volume due to industrial growth, while Europe prioritizes sustainable, eco-friendly coatings.

Challenges & Opportunities

Challenges:

-

High upfront investment in powder coating equipment

-

Difficulty coating complex geometries

-

Competition from liquid coatings in specific applications

Opportunities:

-

Development of low-temperature curing powders for heat-sensitive substrates

-

Market expansion in emerging economies with growing industrial and automotive sectors

-

Innovative aesthetic finishes targeting premium consumers

Future Outlook

Sustainability, technological innovation, and industrial demand will continue to shape the powder coatings market. Companies focusing on eco-friendly solutions and automation are expected to gain a competitive edge in this evolving industry.

For more detailed insights, contact us: Contact Us

Read: Fertilizer Market Trends, Technology & Forecast by 2034